Producten:Electro filters: Trion Electrostatische filters

TRION Air Boss ATS Purification systems

Air Boss ® ATS There are certain things you expect from an air purification system.

A perfect fit for your specific application...effectiveness... availability. For even more value, add a variety of applications and simplicity of operation. Back all these features up with substantial product and application expertise, superb technical services and unconditional support anywhere, anytime, and you’ve got the first name in air purification systems: Trion.

Since 1947, Trion has combined the leading-edge technology you expect with the value-added services you want to provide unique, effective air purification solutions for numerous applications in industrial and commercial markets.

T 4002 FEATURES AND BENEFITS

Trion Models T1001, T2002, T4002, T6002 and T8002 are high efficiency electrostatic modules for

in-duct installation where air movement is provided by other external sources.

Power Supply - Solid state unit mounted in external housing which also incorporates door operated electrical safety interlock switch. Neon lamps provide ‘Mains On’ and ‘HTON’ indication. The output of the Ionizer = 12Kv, the Collector = 5.9Kv.

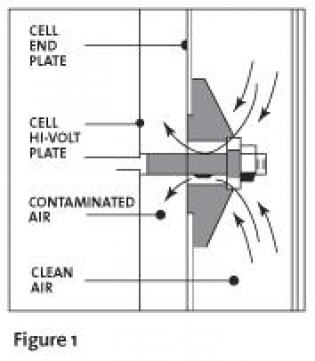

Each alternate plate is charged with the same polarity as the particles, which repel, while the interleaving plates, which are grounded, attract and collect oil/coolant mist, and smoke. The air is then returned fresh and clean.

High Voltage Insulator

The high voltage components in the ionizing/collector cells are supported with insulators of a completely new design. A strategically located air passage and venturi spacer, direct clean air at increased velocity across critical areas of the insulator. These areas, under positive pressure, force contaminated air away from the insulator (see Figure 1) creating the following benefits:

Insulators stay clean, improving overall collecting efficiency.

Higher percentage of water in soluble oil can be collected.

Reduced maintenance.

How it works

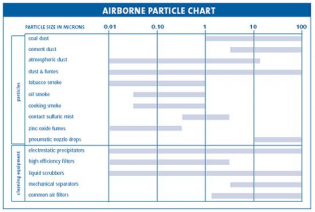

Trion’s VOMP 600 utilizes the principle of electrostatic precipitation. Air is drawn by the motor/blower through an impinger prefilter which traps large particles. Remaining particles, some as small as 0.01 microns, pass into a strong electrical field (ionizing section) where the particulate receives an electrical charge. The charged particles then pass into a collector plate section made up of a series of equally spaced parallel plates.

VOMP 600 - Vertical Oil Mist Precipitator

Description

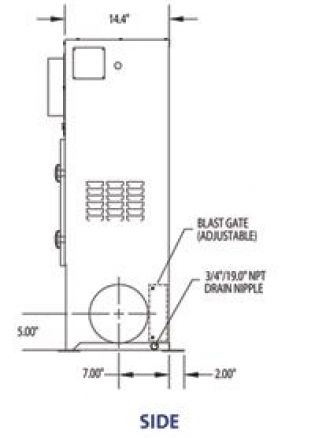

Trion’s Vertical Oil Mist Precipitator (VOMP) 600 electronic mist collector is designed to remove oil/coolant mist and smoke at the source. The VOMP 600 brings you in compliance with OSHA and EPA standards, improves employee safety and working conditions, protects equipment, plant fixtures and work in progress, and reduces plant maintenance costs. The VOMP 600 can be mounted directly on the machine tool for source capture of contaminants such as water-soluble, synthetic and petroleum-based coolants and smoke.

Applications

The VOMP is ideal for:

Screw machines

Surface and centerless grinders

CNC machining centers

Turning lathes

Parts cleaning systems

Various other applications

Features & Benefits

High efficiency – up to 95% efficient on 0.3 micron particles.

Cleans and re-circulates indoor air – no expense to reheat or cool air.

Wall, platform or machine mounting – eliminates the need for elaborate duct work and saves floor space.

Can be wired directly to the machine tool control – operates only when the machine tool does.

Spiked ionizer increases efficiency and reliability.

Collector cell is made of all-aluminum plates, which eliminates filter replacement costs.

Low airflow resistance reduces energy costs.

Venturi-assisted high-voltage insulator forces clean air across critical areas of the insulator to provide longer service intervals.

Power Supply - Solid state unit mounted in external housing which also incorporates door operated electrical safety interlock switch. Neon lamps provide ‘Mains On’ and ‘HTON’ indication. The output of the Ionizer = 12Kv, the Collector = 5.9Kv.

Pre-Filter - Close weave aluminium mesh uniformly distributes fume laden air and collects large particles.

Ionizer Cell - Spiked saw blade type plates are fitted on all Trion T-Series units. They have the advantage over standard tungsten wires for more effective air cleaning efficiency and an almost unlimited life span.

TRION Air Purification systems

Trion Models T1001, T2002, T4002, T6002 and T8002 are high efficiency electrostatic modules for

in-duct installation where air movement is provided by other external sources.

Numerous applications. One solution.

When you need one system for cleaning numerous applications, such as kitchen grease and smoke, oil mist, and contaminants from other industrial processes, Trion has the kitchen exhaust, commercial, and large industrial solutions just for you.

Atmospheric contaminants may be either liquids or solids, in the form of oil, water, grease, smoke, fumes, dusts or similar particulate including gaseous and vaporous odors.

The Model 75 readily adapts to the various air collection methods utilized to recover contaminants for collection. Air inlet and outlet flanges on the modules include predrilled holes to connect adjoining duct work.

Module support rails are optional for multiple mounting methods.

With your unique needs in mind, the Trion Model 75 utilizes five individual sections, each with specific air treatment tasks that are pre-selected, then factory assembled to form a compact, inline, drop-in unit. The modules and their basic functions include:

Module NameNormal FunctionPrefilter/ImpingerMist Eliminator/Grease ExtractionESP-Electrostatic PrecipitatorHigh-efficiency Primary

or Secondary Filtering DeviceMediaPrimary, Secondary or Backup FilterAdsorber Odor Control and RemovalBlower System Air Mover

TRION MODEL 75 Air Purification systems

There are certain things you expect from an air purification system.

A perfect fit for your specific application... effectiveness...availability. For even more value, add a variety of applications and simplicity of operation. Back all these features up with substantial product and application expertise, superb technical services and unconditional support anywhere, anytime, and you’ve got the first name in air purification systems: Trion.

Since 1947, Trion has combined the leading-edge technology you expect with the value-added services you want to provide unique, effective air purification solutions for numerous applications in industrial and commercial markets.

Features/Benefits

Straight through or side discharge — ability to better control airflow

(M3000 & M6000)

Odor and High Efficiency Filters — from HEPA and adsorber modules to mini-pleat filters (194/388 sq. ft.) for maximum efficiency and effectiveness

(M3000 & M6000)

Belt driven blower with variable pitch sheave — providing adjustment for precise CFM operating range (M3000 & M6000)

Collects wet or dry particulates providing versatility in a wide range of applications (M3000 & M6000)

High static blower packages — capacity for additional external static offers more contaminant pickup points (optional for M3000)

How It Works

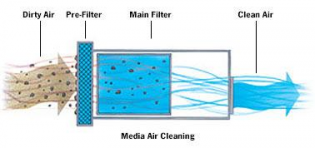

Trion’s Air Boss Media Series uses the Interception Filtration Principle. Dirty, polluted air is drawn through the pre-filter to remove larger dust particles. The second stage, micro-glass deep pocket media filter removes submicron particles from the air stream by interception. The small diameter fibers in the filter intercept and retain these small particles while the large surface area of the filter gives long life and low pressure drop. The blower is designed specifically to handle the filtration system at rated CFM over the useful life of the filter.

TRION M6000 Air Purification systems

Engineered Solutions For Clean Air

Trion’s AIR BOSS media units are industrial air cleaners designed for both general ventilation (removal of airborne pollutants from plant atmospheres) or source capture (ductwork or arms positioned at the origin of pollutants). These units help solve welding smoke, oil mist, rubber dust, diesel smoke, grinding dust, numerous gases/odors and many other indoor air pollution problems.

How it works

Ceramic insulators — out of airstream for increased reliability

Extra depth collector cell — more dirt holding capacity and stays on line longer

Spiked ionizer — no ionizing wires to replace, reducing maintenance and replacement cost

High efficiency — up to 95% on single pass and 99% on double pass option

Permanent ionizer/collector elements — no filter replacement cost; just wash, dry and reinstall

Low pressure drop — lower energy cost to operate compared to media and cartridge units

Hinged access — no tools required for quick and easy service

How It Works

Trion’s T Series utilizes the principle of Electrostatic Precipitation. Air is drawn by the motor/blower through a washable metal mesh pre-filter which traps large dust particles. The remaining particles, some as small as 0.01 microns, pass into a strong electrical field (ionizing section) where the particulate receives an electrical charge. The charged particles then pass into a collector plate section made up of a series of equally spaced parallel plates. Each alternate plate is charged with the same polarity as the particles, which repel, while the interleaving plates are grounded, which attract and collect.

TRION T SERIES Air Purification systems

Engineered Solutions For Clean Air

Trion’s T Series is ideal for the removal of smoke, fumes, and oil/coolant smoke and mist.

The T Series has the ability to clean contaminated indoor air and recirculate it back to the work area, reducing energy costs by not having to exhaust conditioned air to the outside. Any of the T Series can be installed free hanging or ducted for source capture.

Features

Solid state power supply

Spiked ionizing blades

Extra depth collector cells

Totally enclosed fan cooled motor

Electrical component box mounted out of air stream

Optional multi-purpose plenum

Motor HP options for added static pressure

Numerous applications. One solution.

When you need one system for cleaning numerous applications, such as kitchen grease and smoke, oil mist, and contaminants from other industrial processes, Trion has the kitchen exhaust, commercial and large industrial solutions just for you.

Atmospheric contaminants may be either liquids or solids, in the form of oil, water, grease, smoke, fumes, dusts or similar particulate including gaseous and vaporous odors. The ATS units readily adapt to the various air collection methods utilized to recover contaminant for collection. Air inlet and outlet flanges on the modules include predrilled holes to connect adjoining duct work. Module support rails are included for multiple mounting methods.

With your unique needs in mind, the Trion ATS design utilizes five individual sections, each with specific air treatment tasks that are preselected, then factory assembled to form a compact, inline, drop-in unit. The modules and their basic functions include:

Pre-Filter - Close weave aluminium mesh uniformly distributes fume laden air and collects large particles. Ionizer Cell - Spiked saw blade type plates are fitted on all Trion T-Series units. They have the advantage over standard tungsten wires for more effective air cleaning efficiency and an almost unlimited life span.